에코바이오홀딩스 주식회사 회원이 되시면 각종 이벤트 할인혜택은 물론, 엘리펫의 다양한 서비스를 보다 안정적이고 효과적으로 이용할 수 있습니다.

Business Areas

BusinessComprehensive consulting

ECOBio is technically certified and consulting based on years of experience and accumulated technology.

Technical Consulting

·Collection and transport

·Pre-treatment of landfill gas

· Landfill gas generation

·Management operation

·Anaerobic digester

·Organic waste pretreatment

·Digestion gas pretreatment

·Digest gas generation

·Biomethane production

·Management operation

·Hydrogen sulfide pretreatment

· Bio-reaethy

·BioSulfar production

·Bio Sulfurization

·Management operation

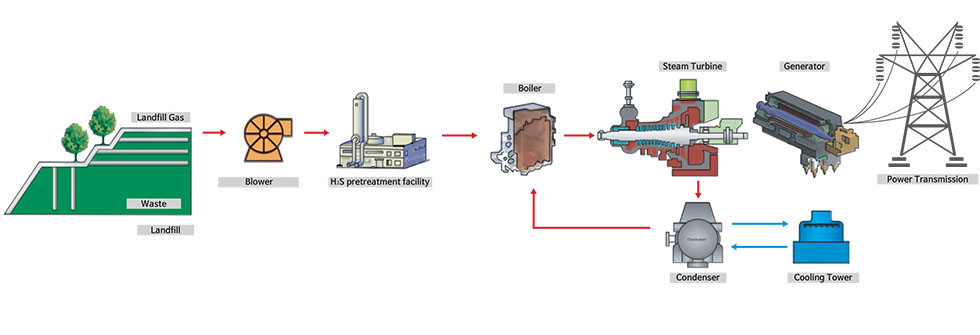

50MW landfill gas power plant in metropolitan area

· Purpose : Utilizing landfill gas as energy source in order to generate electricity whereas creating added value to the economy.

Minimizing the negative environmental impact of its surroundings and contributing to the prevention of global warming

· Size : 50MW (world's largest landfill gas generating capacity)

Produce eco-friendly biohwang (pre-treatment)

· Production : Remove hydrogen sulfide (H2S) from the flow of mixed gas and produce it through microbial metabolism

· application : Available in fertilizers/documents, daily necessities, cosmetics, medical supplies, etc.

Bio energy

·Purpose : It has its purpose on stabilizing organic wastes, such as food wastes, drinking waste from Wonju city, to convert them into a type of energy that’ll replace e fossil fuels, converting biogas into energy withal creating an eco friendly environment.

·Daily load : 220 tons/day

·Biogas purification

- Facilities Capacity: 600Nm3/hr

- Methane gas production:4,100m3/day

- Process composition: anaerobic digestion gas → biogas pretreatment, purification → compressed storage → supply

·Wastewater treatment

-Processing method: biological treatment + pressure injury

-Facilities Capacity: 200 tons/day

·Sludge treatment

-Dehydration method : screw press Type

-Processing capability :18m3/hr, 2units

-Moisture content:77%Below

Hydrogen station

·Usage : Fuel cell vehicle charging and fuel cell power generation(20kW)

·Built the world's first hydrogen production facility using landfill gas

·Establishment of clean, pollution-free fuel cell vehicle

·Hydrogen gas generator(30Nm3/h), wjwkddydrl(0.72m3×8units), Charger(2th)

·Fuel cell [Up to 10kW x 2units], Gas analyzer system, Surveillance control equipment, PR room

·Facility utilization

-Landfill gas’s hydrogen production technology accumulation. Accumulating hydrogen production technology from landfill gas.

Furthering the progress of automobile hydrogen fuel cell development and diffusion. And promoting power generation facilities that use hydrogen filling station and power plant operation test beds.

- Increase public awareness of hydrogen fuel cell power generation and charging stations to not only experts in the field but ordinary citizens.